Works

- home

- Works

SOLUTION FOR CANNING FOOD

The process of food packaging usually generates dead times for lack of automation in manufactury stages which are still performed manually.

Amaro &

Amaro developed an engineering solution what consists in an automatic lid

positioning machine for the packaging industry.

The manufacturing device operates

automatically according to the program loaded by the datalogger on the

production line.

The industrial engineering company Amaro & Amaro

developed an automatically lid feeder. The industrial device that

automatically positions of various sizes and lid formats for food packaging: supports

industrial production with ¼, ½, 1 or 4 liter containers.

Before: the problem

In the packaging line the containers passed through the

conveyer

belt until the filler machine. Then they were manually capped by an human operator.

But for correct fitting or threading always is necessary to pre-position of

tamp, and do it obstruct the product performance. So the line had a difficulty:

could never exceed 100 containers per minute

After: the

solution

The engineering

solution was the development of an automatic lid feeder to automated a

mechanical task that does not add value to the productive process.

The

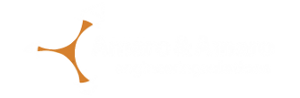

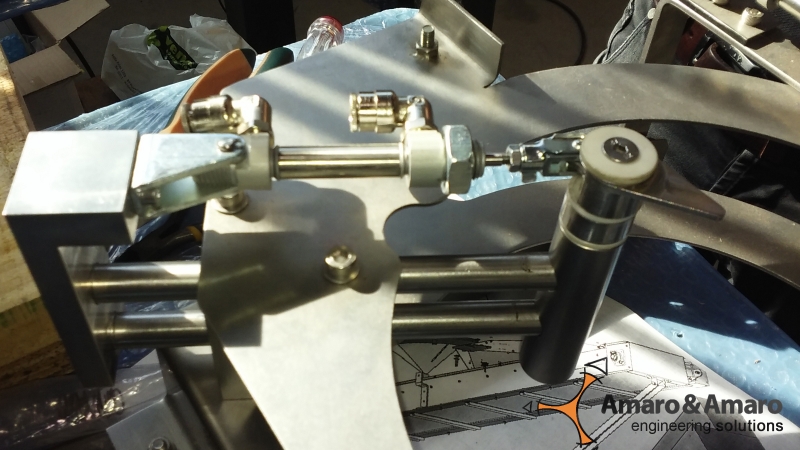

manufacturing device has a bulk hopper and a slide that moves the pieces in the

closed position and admits different sizes of packaging.

It also

includes an optical sensor that detects the speed of the line to dispense,

order, position and release a lid just on each container.

The entire

automation process is attached to the filling line without making any

modifications to the infrastructure.

When the system detects the

caps in the wrong position, proceed to divert them to a collector channel to

returns them for re-positioning.